HEBRON, Ohio — Used at many of MPW’s Build-Own-Operate-Maintain (BOOM) sites, the Mobile Silica Lab provides a fully-automated, continuous analysis of silica levels in deionized – demineralized product water. This technology was developed in MPW’s engineering department and implemented beginning June 2013.

HEBRON, Ohio — Used at many of MPW’s Build-Own-Operate-Maintain (BOOM) sites, the Mobile Silica Lab provides a fully-automated, continuous analysis of silica levels in deionized – demineralized product water. This technology was developed in MPW’s engineering department and implemented beginning June 2013.

MPW’s traditional technology required a manual sample, whereas this technology is automatic. However, if desired, a manual sample can be taken from an easy-access faucet inside the mobile lab.

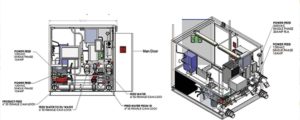

It features a Hach 5000 Silica Analyzer, a Thornton M800 Transmitter, a Thornton Conductivity Sensor, an Allen-Bradley Virsa View 1500 and a Rosemount 880D Vortex Flow Meter. The Silica Analyzer collects data such as the silica level, conductivity, water flow rate and temperature from the DI trailers on-site. This technology aids in preventing contamination of the customer’s tanks if the silica levels are above the desired level.

MPW’s technology is capable of automatically detecting unwanted levels and diverting the water away from the customer’s tank.

The vessel in which the lab technology is housed is 10’x8’x8’6” and weighs 3,700 pounds. The vessel can be operated using three different power options: 3 120V, 15A w/AC 2 120V, 15A 1 240V, 30A MPW strives to improve our existing technologies and develop new technologies to assist our customers.