Problem

An outdated deionization (DI) system in the paint-booth area of an Ohio automotive plant was failing to produce an acceptable quality of water and necessitated excessive chemical costs to meet approved throughput levels. Additionally, chemical leakage was causing damage to floors, valves and pumps near the system. Conductivity of influent city feedwater measured approximately 700 μS/cm, which forced the dual-train system to regenerate several times per day.

Solution

For more than 20 years, MPW has provided 24/7 operational support at this location. Upon discovering the client’s DI dilemma, MPW managers contacted Engineering and Field Services team members, who inspected the water system and analyzed the source water.

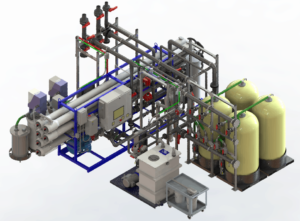

To replace the aging water system, MPW’s in-house Engineering and Fabrication teams designed, delivered and installed a customized single-pass reverse osmosis (RO) system that was more reliable and produced a higher quality of water, easily meeting the plant’s specifications. Additionally, MPW’s chemical-delivery system was double contained from the tank to the injection point, eliminating dangerous chemical leaks.

Another factor in the efficiency of MPW’s DI and RO systems is the use of high-density polyethylene (HDPE), a corrosion-resistant piping option that can drastically improve reliability over polymer vinyl chloride (PVC) pipes. Compared to PVC, HDPE is more resistant to freezing, leeching and UV degradation.

Results

MPW’s automated RO system improved water quality, increased reliability, removed the safety risks associated with leakage and reduced operation costs by 40 percent.